Tube Inspection

Tube Inspection (MFL)

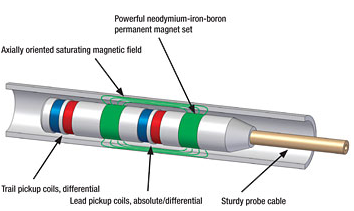

Magnetic Flux Leakage Services (MFL) is an advanced NDT technique which has the inspection capability in wall loss detection and measurement of sharp defects such as pitting, grooving and circumferential cracks in ferromagnetic materials. The working principle of MFL involves the induction of a magnetic field in the part to be tested and the response or signal produced is analyzed to determine the presence and characteristics of defects.

MFL uses a powerful magnet to magnetize the conductive material under test. Where there are defects- corrosion or material loss- the magnetic field “leaks” from the material. MFL probes incorporate a magnetic detector placed between the poles of the magnet where it can detect the leakage field.

During the inspection, a magnetic circuit of sorts forms between the part and the probe. The magnetic field induced in the part saturates it until it can no longer hold any more flux. The flux overflows and leaks out of the pipe wall and strategically placed sensors can accurately measure the three-dimensional vector of the leakage field.

Because magnetic flux leakage is a vector and that a sensor can only measure one direction, any given probe must have three sensors to accurately measure the axial, radial, and circumferential components of an MFL signal.

Some of the Benefits of MFL are:

1) One of the few methods to inspect finned tubes

2) Can be used on all ferromagnetic materials

3) Good sensitivity to ID pitting and corrosion

4) High-speed inspection.

Remote Field Testing (RFT)

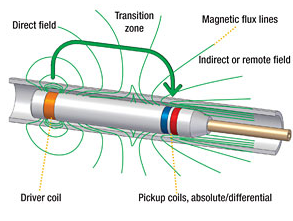

Remote field testing Services (RFT) is an electromagnetic method of testing whose main application is finding discontinuities in steel pipes and tubes. An RFT probe is moved down the inside of a pipe and is able to detect inside and outside discontinuities with approximately equal sensitivity (although it cannot discriminate between the two).

RFT probe consists of an exciter coil (also known as a transmitter or send coil) which sends a signal to the detector (or receive coil). The exciter coil is pumped with an AC current and emits a magnetic field. The field travels outwards from the exciter coil, through the pipe wall, and along the pipe. The detector is placed inside the pipe two to three pipe diameters away from the exciter and detects the magnetic field that has travelled back in from the outside of the pipe wall (for a total of two through-wall transits). In areas of metal loss, the field arrives at the detector with a faster travel time (greater phase) and greater signal strength (amplitude) due to the reduced path through the steel.

Remote Field Testing (RFT) is being used to successfully inspect ferromagnetic tubing such as carbon steel or ferrite, or stainless steel & Non- ferromagnetic material such as brass & copper. This technology offers good sensitivity when detecting and measuring volumetric defects resulting from erosion, corrosion, wear, and baffle cuts.

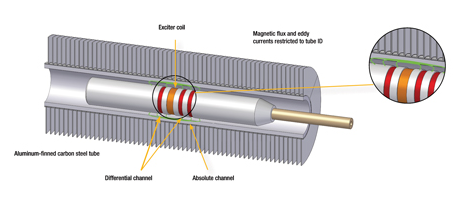

Near Field Testing (NFT)

Near field testing (NFT) technology is a rapid and inexpensive solution intended specifically for fin-fan carbon-steel tubing inspection. This new technology relies on a simple driver-pickup eddy current probe design providing very simple signal analysis.

NFT is specifically suited to the detection of internal corrosion, erosion, or pitting on the inside of carbon steel tubing. The NFT probes measure lift-off or “fill factor,” and convert it to amplitude-based signals (no phase analysis). Because the eddy current penetration is limited to the inner surface of the tube, NFT probes are not affected by the fin geometry on the outside of the tubes.

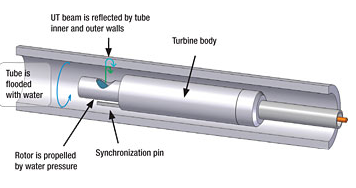

Internal Rotary Inspection System (IRIS)

Along with other advanced techniques IXAR has initiated the Internal rotary inspection system (IRIS) ultrasonic test method which is employed for testing pipes and tubes in boilers, heat exchangers and fin-fan tubes. The IRIS probe is inserted into a tube that is flooded with water, and the probe is pulled out slowly as the data is displayed and recorded. The ultrasonic beam allows the detection of metal loss from the inside and outside of the tube wall. The IRIS probe consists of a rotating mirror that directs the ultrasonic beam into the tube wall. The mirror is driven by a small turbine that is rotated by water pressure.

As the probe is pulled the spinning motion of the mirror results in a helical scan path. The IRIS probe must be moved very slowly (approximately 2.5 cm/s) to produce very accurate results (wall thickness measurements typically accurate to within 0.13 mm). Not sensitive to cracks aligned with tube radius.

Benefits of using IRIS include:

1) Suitable for ferrous and non-ferrous materials

2) Detection of corrosion, pitting and wall-loss

3) Accurate wall thickness measurements

4) Sensitivity to both internal and external discontinuities.

5) Discontinuity position can be located in relation to tube length

6) 100% coverage of tube

7) Works on all materials, regardless of properties

8) Flexibility as a backup to a remote field, magnetic flux leakage and eddy current inspections.

IXAR inspectors have years of experience using IRIS and they can provide you with an accurate assessment of the conditions of your components and Total Quality Assurance.